A Game-Changer for Durability and Performance

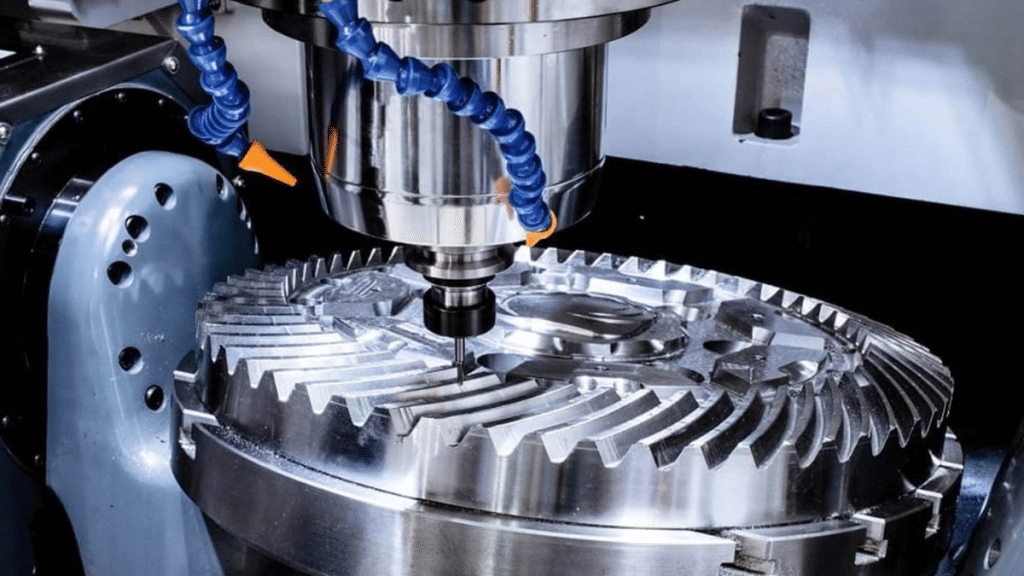

In the hectic world of accuracy production, every element matters. Coming from automobile motors towards aerospace turbines as well as clinical implants, CNC-machined components deal with extreme needs for resilience, effectiveness, as well as dependability. Go into Diamond-Like Carbon dioxide (DLC) coatings—a revolutionary service that integrates diamond-like firmness along with graphite-like lubricity towards change element efficiency. Within this particular short post, our team check out exactly just how DLC coverings function, their advantages, as well as why markets are actually relying on this progressed innovation towards remain in advance.

In the hectic world of accuracy production, every element matters. Coming from automobile motors towards aerospace turbines as well as clinical implants, CNC-machined components deal with extreme needs for resilience, effectiveness, as well as dependability. Go into Diamond-Like Carbon dioxide (DLC) coatings—a revolutionary service that integrates diamond-like firmness along with graphite-like lubricity towards change element efficiency. Within this particular short post, our team check out exactly just how DLC coverings function, their advantages, as well as why markets are actually relying on this progressed innovation towards remain in advance.

Exactly just what Are actually DLC Coverings?

A Game-Changer for Durability and Performance

DLC coverings are actually thin-film carbon-based levels put on substrates such as steel, titanium, or even porcelains utilizing progressed methods like Bodily Vapor Deposition (PVD) or even Plasma-Assisted Chemical Vapor Deposition (PACVD). These coverings imitate the residential or commercial homes of all-organic ruby, providing remarkable firmness (15-30 GPa or even 2000-5000 HV), reduced rubbing coefficients (0.1-0.25 completely dry out, <0.1 lubricated), as well as outstanding chemical inertness.

Irish government could charge asylum seekers for accommodation

Along with thicknesses varying coming from 1-5 microns as well as deposition temperature levels as reduced as 170-200°C, DLC coverings are actually flexible sufficient for a wide variety of requests without jeopardizing substratum stability.

Why DLC Coverings Outperform Conventional Options

Compared with conventional coverings such as Titanium Nitride (TiN) or even Chromium Nitride (CrN), DLC coverings deal exceptional efficiency in essential locations:

DLC's rubbing coefficient is actually 200-500% less than TiN as well as CrN, creating it perfect for requests needing very little use as well as soft procedure, like moving elements or even reducing devices. While TiN as well as CrN master high-temperature atmospheres, DLC's low-temperature deposition procedure creates it suitable along with delicate substrates such as specific steels or even titanium alloys, expanding its own charm.

Real-World Requests of DLC Coverings

DLC coverings are actually changing markets through improving the efficiency of crucial CNC elements:

Automobile: Piston bands, equipments, as well as shutoff educate elements take advantage of DLC's reduced rubbing as well as use protection, decreasing gas usage as well as prolonging component lifestyle.

Aerospace: Reducing devices as well as turbine cutters covered along with DLC endure severe problems, enhancing effectiveness as well as decreasing upkeep sets you back.

Clinical: DLC's biocompatibility (certified along with ISO 10993) creates it ideal for medical devices as well as implants, guaranteeing resilience as well as security in delicate requests.

Komentar

Posting Komentar